This French-speaking SME specializes in the manufacture of lighting fixtures. It has switched to Monday Work Management

Our customer, a company specialized in the manufacture of high-end lighting fixtures, manages a product lifecycle of considerable complexity, from design to maintenance. The company's value chain is extensive, starting with tender follow-up and prototype calculations, continuing with contracting, and culminating in project follow-up by the design office and production workshop. Once the luminaires have been manufactured, logistics extend to the worksite, requiring coordination of installation teams and external partners.

Until now, this end-to-end orchestration was based on a set of traditional, but fragmented, working methods: information was stored in isolated Excel files, communications were via e-mail exchanges, and planning relied largely on employees' memories and post-it notes. This lack of a centralized tool created numerous information silos and inefficiencies.

The company therefore identified a crucial need: the implementation ofa solution capable of integrating and centralizing all its activities. It was looking to gain an overview of the entire lifecycle of its products, from the first response to a call for tenders to the planning of field interventions.

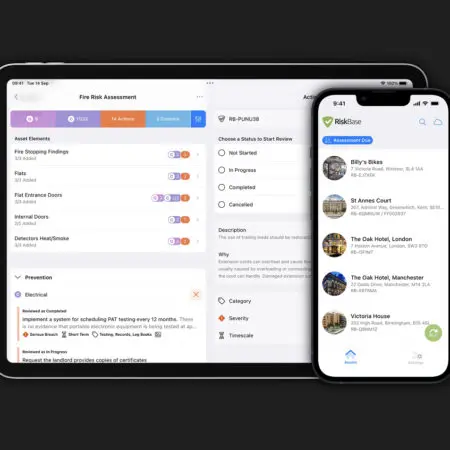

To meet its centralization and coordination needs, the company turned to Monday Work Management. Rather than adopting a rigid solution, Monday s flexibility made it possible to build a tailor-made platform, perfectly suited to the company's complete product lifecycle. The implementation focused on several key areas, transforming the entire value chain.

It has been able to replace traditional tools with a single, collaborative platform, making communication more fluid, ensuring better coordination between teams and optimizing production and project tracking.

The design office, manufacturing workshop and field teams work on a single platform, ensuring real-time visibility of the status of each project. This transparency has put an end to information silos and drastically reduced email exchanges and follow-up calls.

One of the main benefits of this transition lies in the automation and use of AI. Repetitive and time-consuming tasks are now handled by the platform. For example, when a prototype is validated, a task is automatically assigned to the production workshop. Similarly, a reminder can be automatically sent to a collaborator at a given deadline, ensuring that no step in the process is forgotten. This has significantly reduced wasted time and costly friction.

Monday s versatility has enabled the company to build a truly tailor-made solution, which not only solves the problems of fragmentation and inefficiency, but also contributes to better collaboration and greater team peace of mind.