For this Swiss toy brand, we created a complete setup integrating all dimensions of the company's activity, to provide a single platform for collecting and distributing information to all stakeholders, software and human alike.

This young Swiss brand sells its products in Switzerland and Europe mainly via its e-commerce site. While it designs and creates products in Switzerland, it delegates marketing, production and logistics to partners in Switzerland, France and Italy. Its vision is to build a company with global performance. One of the dimensions of which - both human and economic - is intelligent working.

Like many growing companies, internal and external processes are struggling to keep pace. The technological infrastructure is fragmented, relying on a myriad of heterogeneous tools. Sales is done on one online platform, accounting uses a separate software package, marketing another for campaigns and newsletters a fourth.

This fragmentation extends to collaboration with the ecosystem of external partners essential to the smooth running of the business. Inventory management, logistics and manufacturing are handled by service providers operating on their own systems.

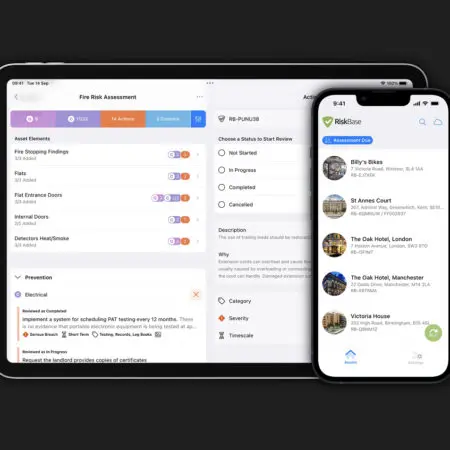

That's why our customer chose Monday to manage its operations.

Implementing Monday has enabled us to move from reactive to proactive management. By centralizing data, the team gains total, real-time visibility across the entire value chain. This single source of truth eliminates information silos, reduces the time spent trying to find out where things stand, and enables more informed decisions to be made more quickly. From strategic directions and product roadmaps to inventory, marketing content, customer CRM and day-to-day tasks, it's all in Monday.

We're on virtual autopilot when it comes to day-to-day operations. It's incredible how much Monday has streamlined business at every level. All information, from strategy to minutiae, wherever it comes from, in one place.

All processes are highly automated, freeing up considerable time. For example, replenishment orders are generated according to stock status, or alerts are issued when certain elements occur, such as an order that has been on hold for too long, a customer request that has not been processed, and so on.